GF12-4, 6000 cans per hour, 250ml 330ml tin can / aluminum can, fruit juice beverage, iced coffee, integrated with filling and seaming machine

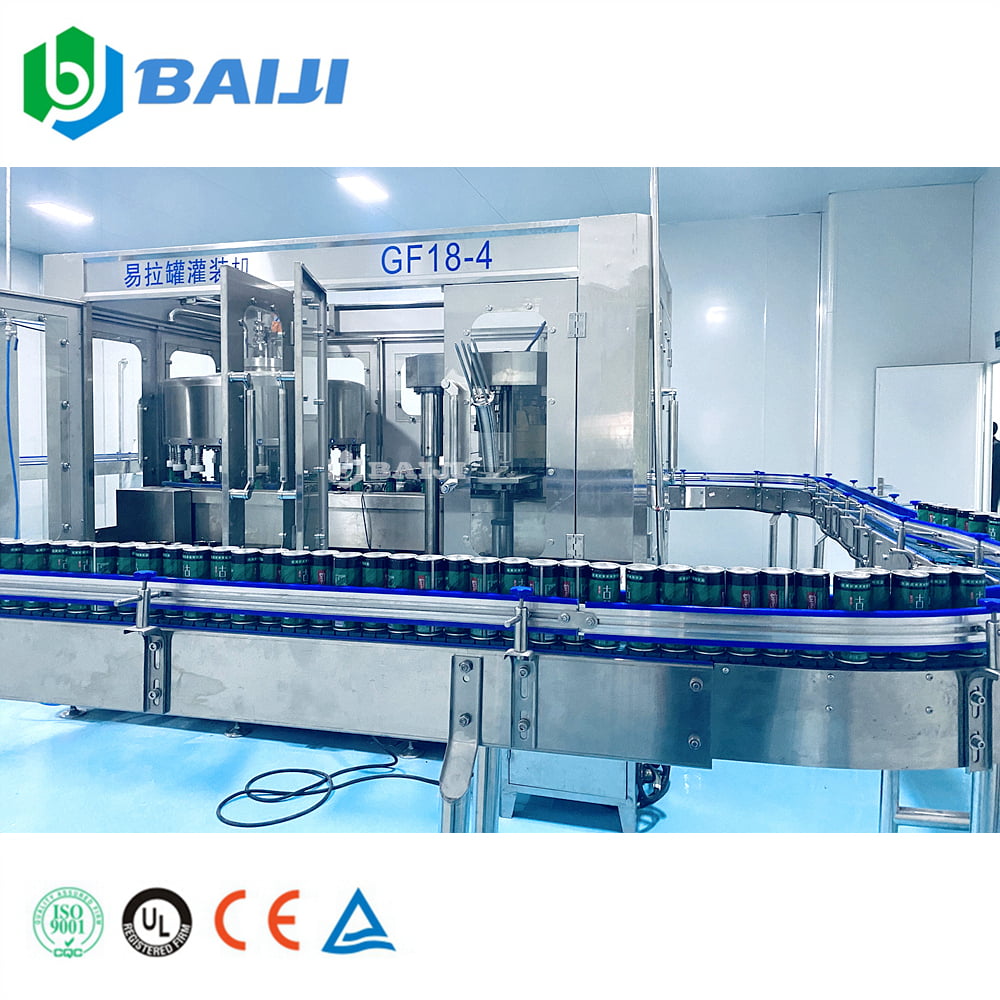

GF series of juice canning machine, it is a monoblock unit, integrated with filling and seaming machine. It is suitable for fruit juice, coffee, tea beverage and so on.

It is mainly designed for hot temperature liquid(85-90℃). If temperature is lower than setting value, filling valves will stop, beverage return to UHT.

Juice blending system

Aluminum can depalletizer

It is designed to handle empty cans from pallets and transfer, layer by layer, onto the production line.

Aluminum can washing

It is revolution inclined type can washer.

Retort machine

The sterilization pot is composed of a pot body, a pot cover, an opening device, locking wedge, safety interlock device, track, sterilization basket, steam nozzle and pipe orifice. The pot cover is sealed by inflatable silicone rubber heat-resistant sealing ring, which is reliable and has long service life.

Automatic PE film wrapping machine

You can have different group style, 24 cans one package, 12 cans one package, etc. It is changeable.

blow dryer |  conveyor system |

water treatment system |  date printer |

SEW motor |  convey lubrication |

automatic lubrication |  oil can be to the main bearing |