Due to the increasingly serious pollution of water sources and the aging of urban water supply pipes, the quality of drinking water is seriously affected. With the general improvement of people's living standard, more and more people begin to pay attention to drinking water health.

So investing in a water plant is a good project.

| Container | Volume | Capacity |

|---|---|---|

| Glass Bottle | 250-1500ML | 2000-12000BPH |

| PET Bottle | 3-10L | 400-2000BPH |

| PET Bottle | 250-2000ML | 2000-30000BPH |

| Barrel | 3-5Gallon | 100-1500BPH |

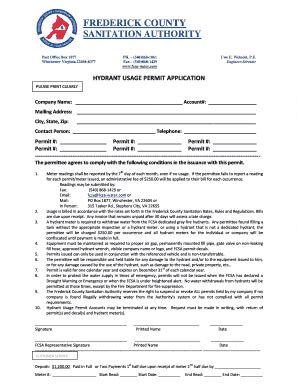

Normally we will need proceed Production License, QS Certification,

Hygiene License and Health Certificate of Employees.

Production License

QS Certification

Sanitation Permit

Practitioner's Health Certificate

Never build a factory far away from the water source, and the nearest distance between the plant and the water source is the best solution.

According to A

Consideration should be given to the presence of nearby sources of pollution, the availability of fresh air, and the availability of off-site drainage channels.

According to B

Factory working house generally need to be 20-50 meters long, 8-12 meters wide. In this range for different applications, such as: bottle blowing room, water treatment room, filling room, packaging room, finished products room and consumable room (preform, cap, label, pe film). The washing filling and capping unit can be specially made into closed workshop.

According to C

Laboratory equipment: microscope, ultra clean table, turbidimeter, acidity meter, analysis balance, regular test of raw water quality and clean water quality.

According to D

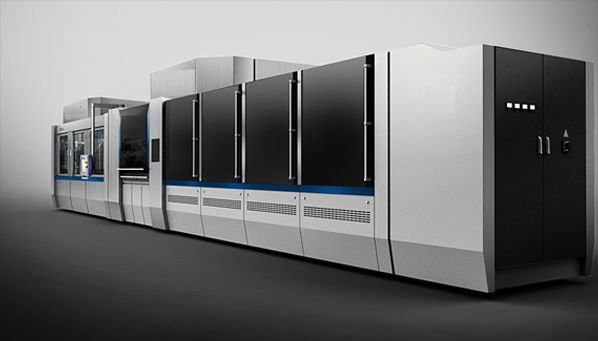

Baiji Machinery Limited can provide you with turnkey solution for complete bottled water filling production line.

We will also send professional engineer to your factory for installation, commissioning and teach your workers how to use our machines.

Here we will list the important components as following:

The production of pure water, the source water can be selected groundwater, tap water, lake water. We can get the water quality report according to the water sample test, so as to configure the corresponding water treatment equipment.

Then we choose the single or two stage reverse osmosis system according to the conductivity of water quality. Normally the water treatment machine mainly including the following equipment: original water tank, water pump, quartz sand filter, activated carbon filter, ion softener, precision filter, RO reverse osmosis, ozone generator and pure water tank.

Sure, if we wanna produce mineral water, we will need use hollow ultrafiltration system to instead of RO system.

Blowing system mainly includes automatic blowing machine, mold, high and low pressure air pressure system, high and low pressure cold drying system, high and low pressure gas storage tank, oil and water separator, water chiller, etc.

The 3in1 filling machine integrates the functions of washing, filling and capping.

Working speed: 2000-30000bph(bottles per hour)

Bottle shape: Round or square bottle or any shape

Bottle size: 200ml-2000ml

Filling Liquid: Mineral Water, Pure Water, Spring Water, Drinking Water and others Non-Carbonated Drinks

At present, the mainstream products are shrink sleeve labeling machine, hot melt adhesive labeling machine and adhesive labeling machine.

The label of hot melt glue is the cheapest, but the price of the machine is also the most expensive. It is most suitable for high speed filling production buyers.

Packing machine we can provide with film shrink wrapping machine or carton packing machine. And we will provide palletizer for finished film packaged or carton packaged products too.

Bottle preform: 0.011CNY/gram*16gram=0.176 CNY, 1PKG is 4.224 CNY

Cap: 0.08 CNY per pcs, 1PKG is 1.92 CNY

Label: around 0.023 per pcs, 1PKG is 0.552 CNY

Labor cost: 0.6 CNY per PKG

Electric cost: 0.4 CNY per PKG

Packing film cost: 0.7 CNY per PKG

If you can give us the order, we will provide A to Z turnkey project to you, and help you to do accurate cost and profit analysis !