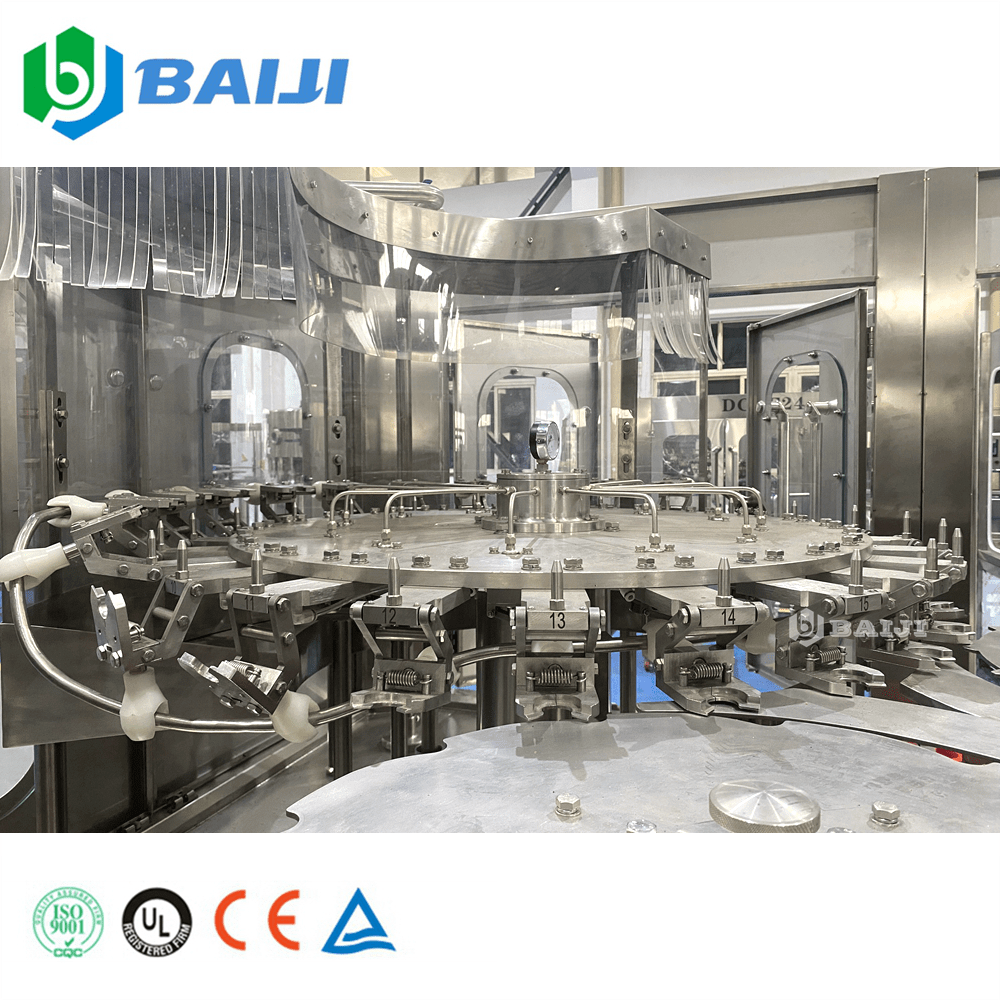

DCGF24-24-8, 6000 bottles per hour, 200ml~2000ml PET bottle, integrated with washing filling and capping machine

DCGF series of carbonated soft drink filling machine, it is a monoblock unit, integrated with washing filling and capping machine. It is suitable for all kinds of carbonated beverage, such as carbonated soft drink, sparkling water, soda water and so on.

Water treatment system

Raw water tank + Raw water pump

Quartz sand filter + Active carbon filter + Sodium ion exchanger + Precision filter

RO Reverse Osmosis ( one stage )

UV sterilizer / ozone generator

Finished water tank + Pure water pump

Carbonated soft drink mixer

It can improve the proportion of water, syrup and carbon dioxide. It is used in carbonated beverage production line and sparkling wine. It is used to cooling the water before mixing which is connected with the mixer.

Automatic Carbonated Drink Bottle Washing Filling Capping 3 in 1 Machine ( Monoblock Type )

It can work for different size bottle from 200ml to 2000ml, but do make sure the same cap. Actually, we can provide different models filling unit according to your speed needs. Min. 2000-3000bph, Max. 24000bph.

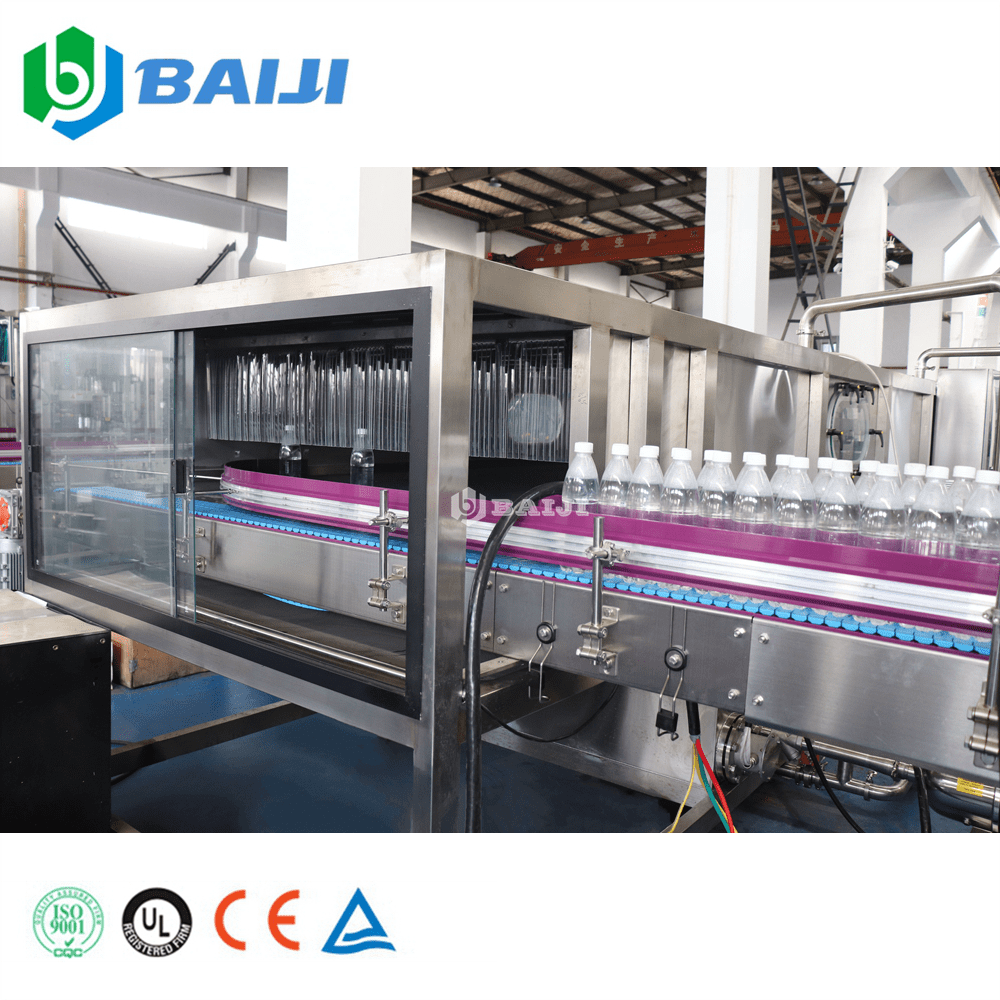

PET bottle warmer

It is used to warm the carbonated drink bottle after low temperature filling, as the carbonated drink after filling, its bottle touch the outside air, it will has a lot small water drops outside, use this machine will warmer it to normal temperature, and after dryer machine, it will be good for labeling.

Automatic OPP hot glue labeling machine

Infeed bottle → pre-position → label cutting → gluing → labeling→ label by press out → finish

Automatic PE film wrapping machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 24 bottles one package, 12 bottles one package, etc. It is changeable.