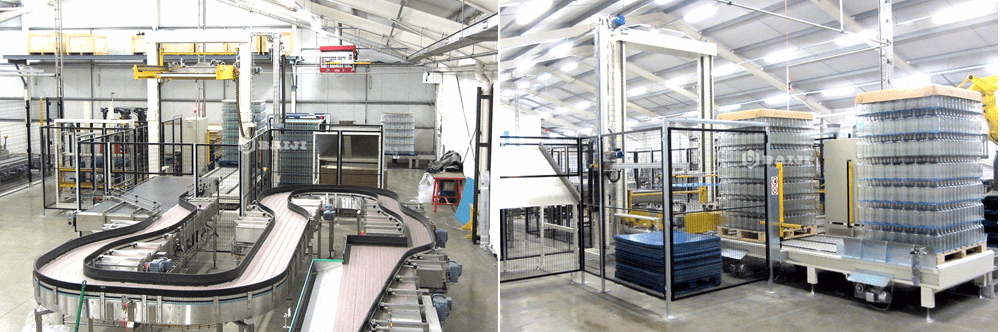

It is aiming to take containers from pallets and load them to the production line for filling or other processes. There is a hydraulic elevator for the pallet under the floor, so compared with a high position depalletizer, the conveyor for pallet and bottles are both lower, that is the reason it is called low position depalletizer. The system is equipped with PLC control system with automatic alarm system to supervise all the machine actions. A wide range of containers such as glass bottles, PET bottles and cans can be handled by this low position depalletizing system.

Features:

The low position bottle depalletizing system is aiming to take containers from pallets and load them to the production line for filling or other processes. There is a hydraulic elevator for the pallet under the floor, so compared with a high position depalletizer, the conveyor for pallet and bottles are both lower, that is the reason it is called low position depalletizer. The system is equipped with PLC control system with automatic alarm system to supervise all the machine actions. A wide range of containers such as glass bottles, PET bottles and cans can be handled by this low position depalletizing system.

| Pallet size | 1200*1000*150 mm |

| Capacity | 800 bottles per minute |

| Applicable containers | PET bottle, glass bottle, aluminum can, tin can |

| Power | 4 KW |

| Weight | 4500 KG |

| Dimension | 6400*3880*2150mm |