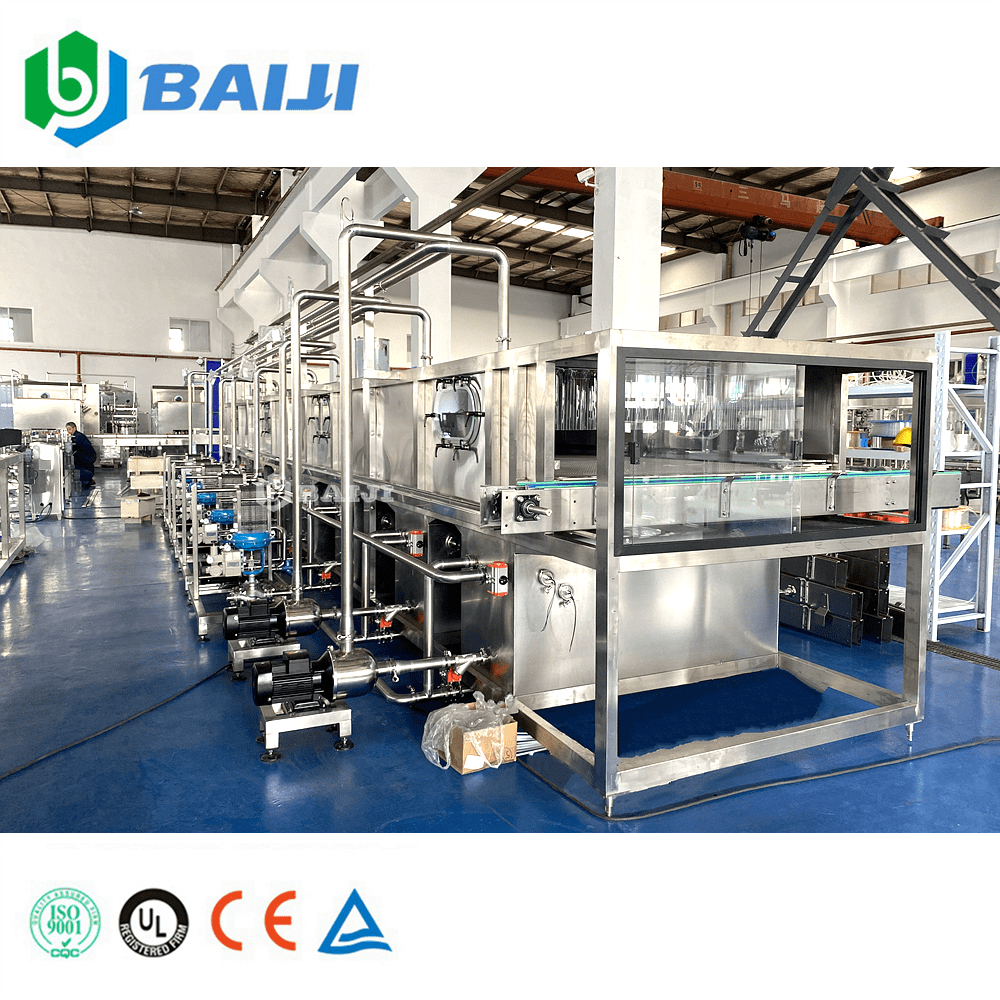

DCGF50-50-15, 15000 bottles per hour, 200ml~2000ml PET bottle, integrated with washing filling and capping machine

DCGF series of carbonated soft drink filling machine, it is a monoblock unit, integrated with washing filling and capping machine. It is suitable for all kinds of carbonated beverage, such as carbonated soft drink, sparkling water, soda water and so on.

Low temperature enhances solubility of CO2. The filling temperature of carbonated beverage is 0~5°C. Before mixing with CO2, the mixture temperature of water and syrup is at 60℃. We need to use a refrigeration unit to reduce the mixture temperature to less than 4℃.

Processing included: quartz sand filter, active carbon filter, sodium ion exchanger, precision filter, RO (Reverse Osmosis), ozone generator, finished water tank.

It can improve the proportion of water, syrup and carbon dioxide. It is used in carbonated beverage production line and sparkling wine. It is used to cooling the water before mixing which is connected with the mixer.

It is mainly used for carbon dioxide drink, such as cola, soda water and so on. 0~5℃ filling, isobaric filling.

Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

It is used to warm the carbonated drink bottle after low temperature filling, as the carbonated drink after filling, its bottle touch the outside air, it will has a lot small water drops outside, use this machine will warmer it to normal temperature, and after dryer machine, it will be good for labeling.

It consists of auto labeling machine, heat shrink tunnel and steam generator.

This machine adopts international advanced technology, cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated.

To pack several bottles into one package, make it easier for delivery.

You can decide 24 bottles one package, 12 bottles one package, etc. It is changeable.

It is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle and oil bottle etc.