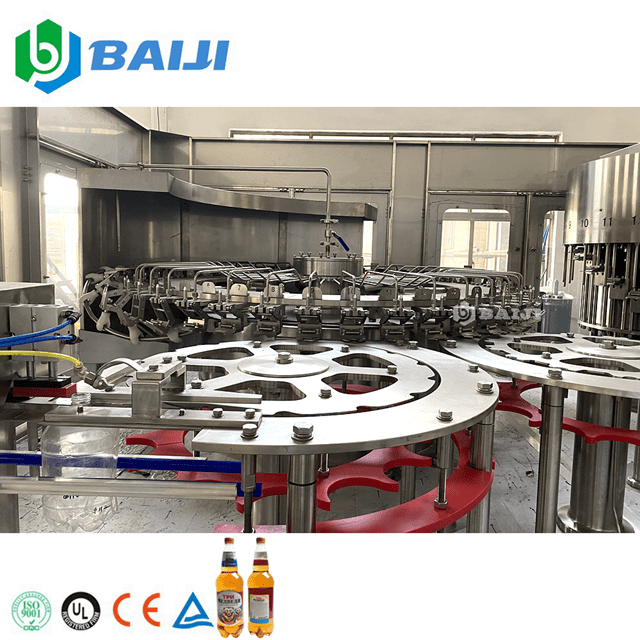

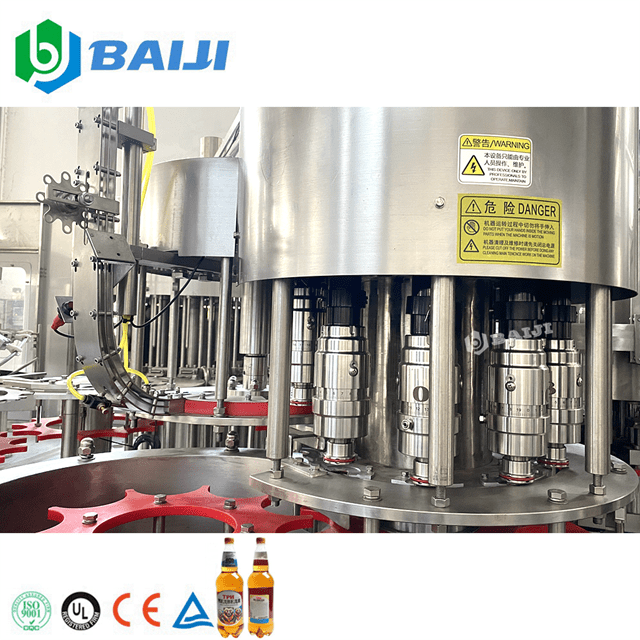

Beer Filling Machine adopts advanced 'Secondary Vacuum and High Pressure Bubble Injection' technology to decrease oxygen content and improve the taste of beer; with precise pressure control and automatic defective bottle detection function, final product of Beer Filling Machine realizes perfect quality at all times.

Features:

We supply complete solution for beer production line, including beer filling machine ( rinsing, CO2 replacement system, beer filling, capping 4 in 1 ), adhesive stick labeling system, PE film wrapping machine & carton box packing machine, also can supply the beer processing system, like saccharification system & filteration system, and fermentation and storage system.

4 in 1 machine

washing, CO2 replacement system, beer filling and capping

Beer brewing system

Complete beer brewing equipment including brewhouse, fermentation tanks, bright beer tank, glycol system, controlling system, beer filling machine etc.

Beer sterilizer

8 temperature sections:

1, preheating: 26℃, 41℃, 50℃

2, sterilization: 68℃ ( heating ), 63℃ ( insulation )

3, cooling: 48℃, 39℃, 28℃

| Model | 24-18-24-10 | 40-24-40-10 | 60-32-60-15 |

| Capacity ( bottles per hour ) | 5000 | 8000 | 12000 |

| Application | beer, craft beer, carbonated beverage and so on. | ||

| Suitable bottle | plastic PET bottle | ||

| Machine material | Food stage SS304 or SS316 | ||

| Control system | PLC+Touch screen | ||

| Features | No bottle no filling No bottle no capping | ||