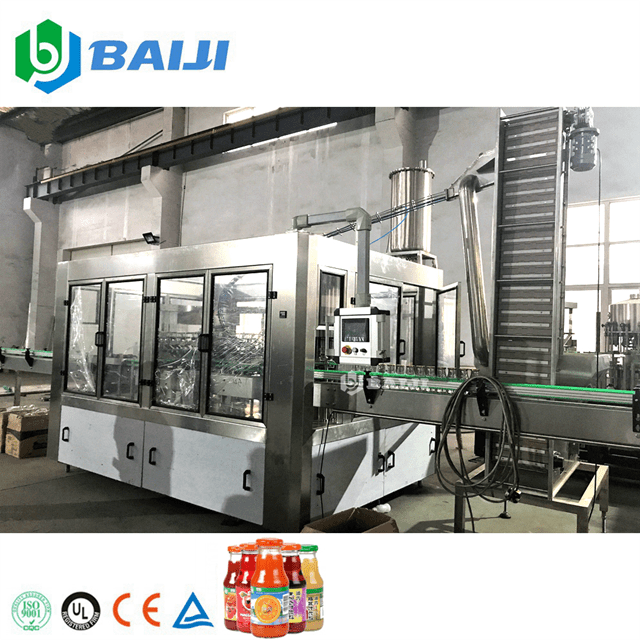

The machine for glass bottle integrates the function of rinsing, filling and capping together. The final filling temperature will be around 85-90 degree centigrade. Once the thermal meter in juice filling machine is lower than the temperature, juice will be return to sterilizing machine again through return system.

Features:

Juice Filling Machine is mainly designed for filling hot temperature liquid.

For example juice, tea drinks etc which are made of concentrate juice.

The final filling temperature will be around 85-90 degree centigrade.

Once the thermal meter in juice filling machine is lower than the temperature, juice will be return to sterilizing machine again through return system.

Juice blending system

Sugar melting tank → syrup filter → blending tank → double filter → storage tank → homogenizer → storage tank → vacuum degasser → storage tank → plate type sterilization

washing filling and capping 3 in 1 unit

Inverted bottle sterilization

Inverted bottle sterilizing machine could overturn bottles(sterilizer glass bottle or PET bottle), which have been filled and sealed, to sterilize inside of bottle mouth and caps by high temperature drink in bottle.

Pasteurization

When enter the spray tunnel, water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling.

Automatic adhesive stick labeling machine

We have different model for your different request, such as single side labeling machine, double sides labeling machine and three sides labeling machine.

Automatic carton box packing machine

To pack several bottles into one package, make it easier for delivery.

You can decide 12 bottles one package, 6 bottles one package, etc. It is changeable.

Model | BCGF8-8-3 | BCGF14-12-5 | BCGF18-18-6 | BCGF24-24-8 | BCGF32-32-8 |

Capacity (500ml) | 2000-3000 | 3000-4000 | 5000-6000 | 8000-10000 | 10000-12000 |

Application | fruit juice, concentrate juice, energy drink, tea beverage and so on. | ||||

Machine material | Food stage SS304 or SS316 | ||||

Filling way/principle | hot filling, 85℃ filling | ||||

Control system | PLC+touch screen | ||||

Features | No bottle no filling No bottle no capping | ||||

Power supply | 220V~415V, 3 phase 50hz/60hz | ||||

Main motor(kw) | 1.5 | 1.8 | 2.2 | 3.0 | 5.5 |

Dimension(mm) | 2200*1600*1800 | 2400*1800*2700 | 2700*2200*2700 | 2800*2330*2700 | 3550*2650*2700 |

Weight(kg) | 2800 | 3500 | 4500 | 5500 | 6500 |