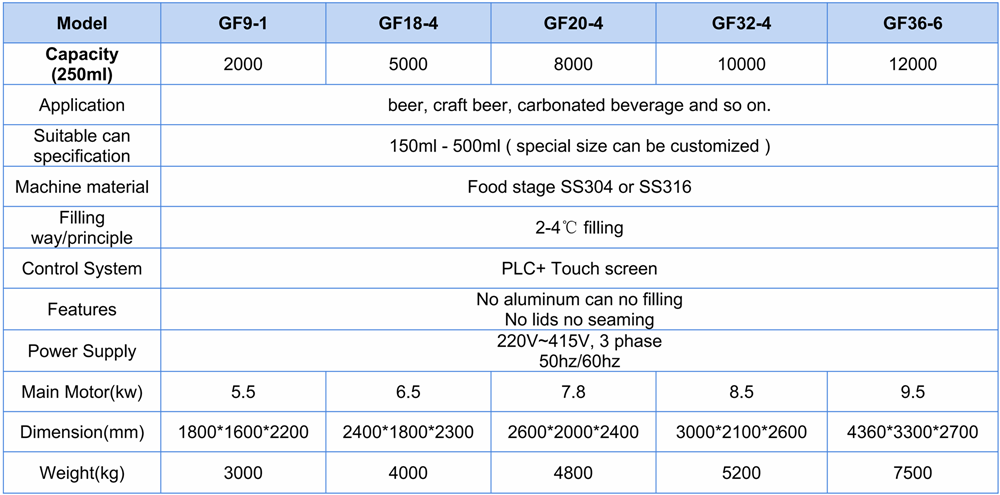

GF9-1, 2000 cans per hour, 250ml, 330ml, 500ml, craft beer, beer, aluminum can filling and seaming machine

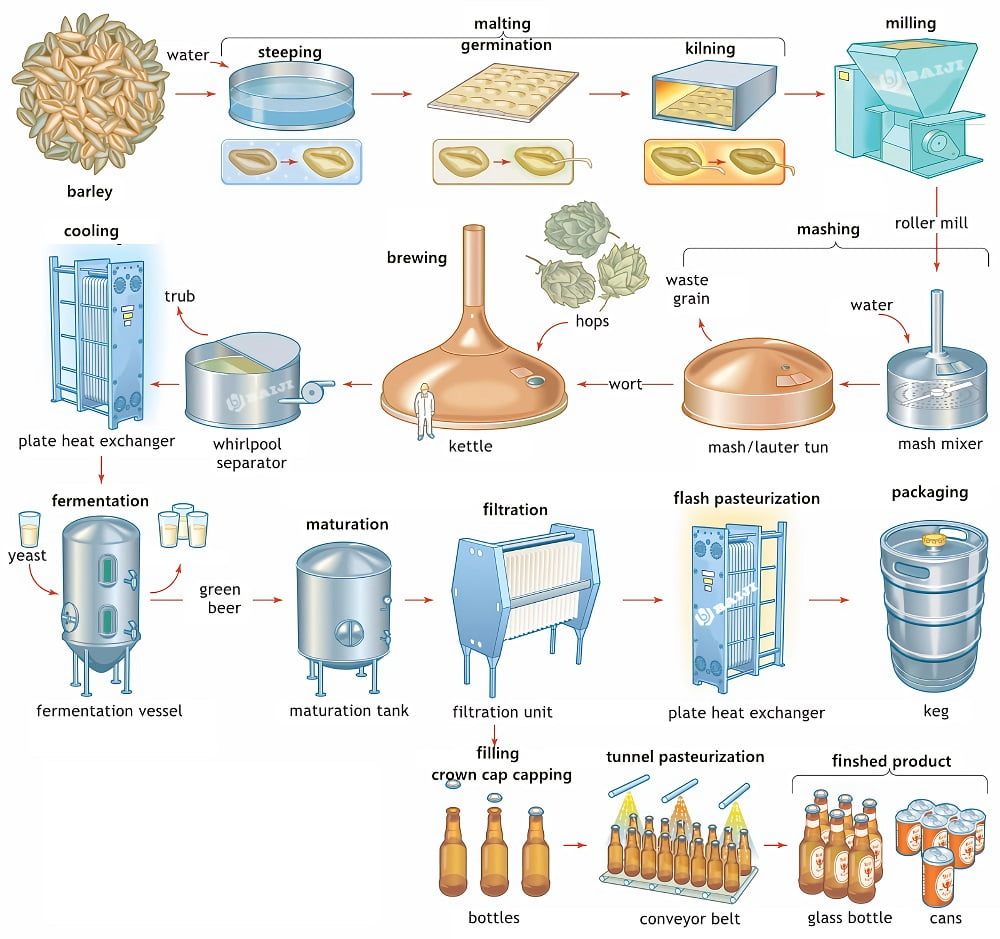

GF series of beer canning machine, it is a monoblock unit, integrated with filling and seaming machine. It is suitable for all kinds of beer, craft beer, ginger beer and so on.

Aluminum can depalletizer

It is designed to handle empty cans from pallets and transfer, layer by layer, onto the production line.

Aluminum can washing

It is revolution inclined type can washer.

Beer sterilizer, including heating, sterilization and cooling section.

Automatic PE film wrapping machine

To pack several cans into one package, make it easier for delivery.

You can have different group style, 24 cans one package, 12 cans one package, etc. It is changeable.

blow dryer |  conveyor system |

water treatment system |  date printer |