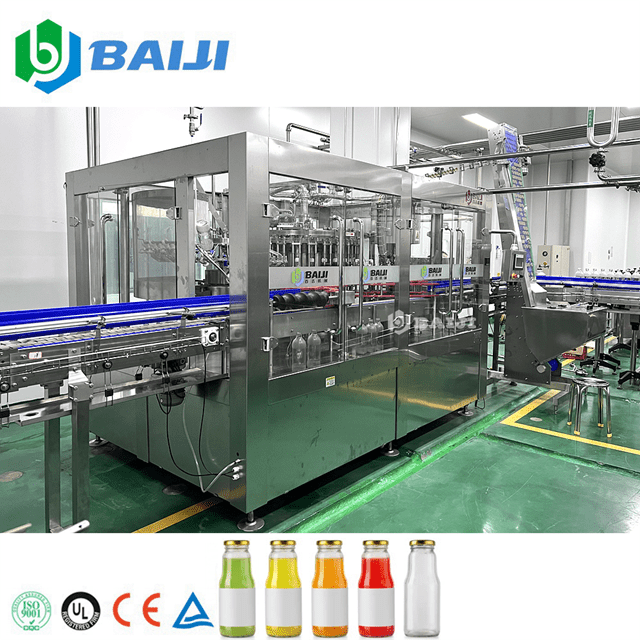

BCGF24-24-8, 8000 bottles per hour, glass bottle, integrated with washing filling and capping machine

BCGF series of glass bottled juice filling machine, it is used for bottling organic fruit juice and concentrate juice, fruit juice with additives, juice with pulp, coffee, flavoured water and so on.

3 in 1 juice filling machine: bottle washing, juice filling, capping

4 in 1 juice filling machine: bottle washing, pulp filling ( >3mm ), juice filling, capping

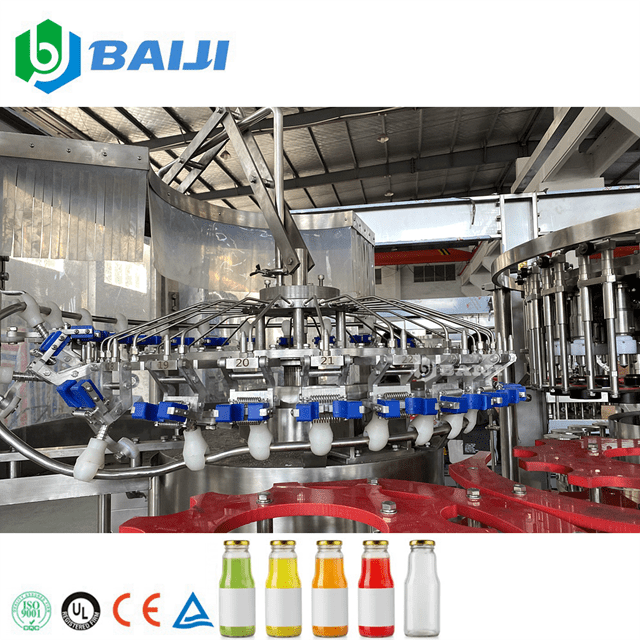

It is mainly designed for hot temperature liquid(85-90℃). If temperature is lower than setting value, filling valves will stop, beverage return to UHT.

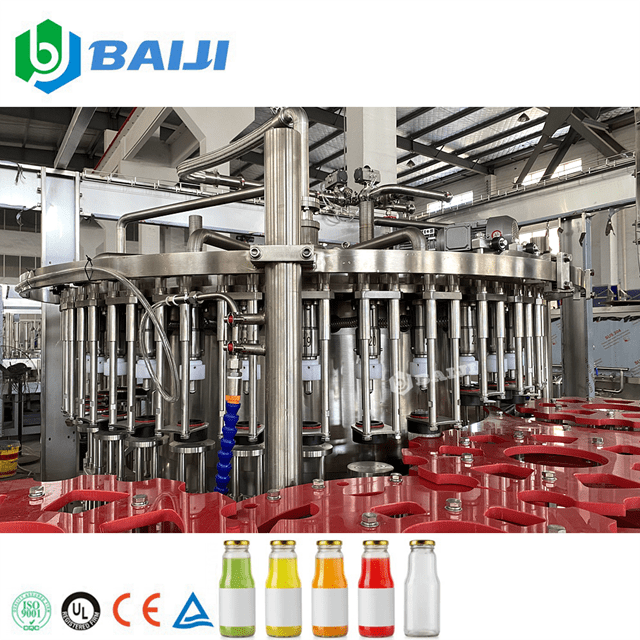

Model | BCGF8-8-3 | BCGF14-12-5 | BCGF18-18-6 | BCGF24-24-8 | BCGF32-32-8 |

Capacity (500ml) | 2000-3000 | 3000-4000 | 5000-6000 | 8000-10000 | 10000-12000 |

Application | fruit juice, concentrate juice, energy drink, tea beverage and so on. | ||||

Machine material | Food stage SS304 or SS316 | ||||

Filling way/principle | hot filling, 85℃ filling | ||||

Control system | PLC+touch screen | ||||

Features | No bottle no filling No bottle no capping | ||||

Power supply | 220V~415V, 3 phase 50hz/60hz | ||||

Main motor(kw) | 1.5 | 1.8 | 2.2 | 3.0 | 5.5 |

Dimension(mm) | 2200*1600*1800 | 2400*1800*2700 | 2700*2200*2700 | 2800*2330*2700 | 3550*2650*2700 |

Weight(kg) | 2800 | 3500 | 4500 | 5500 | 6500 |

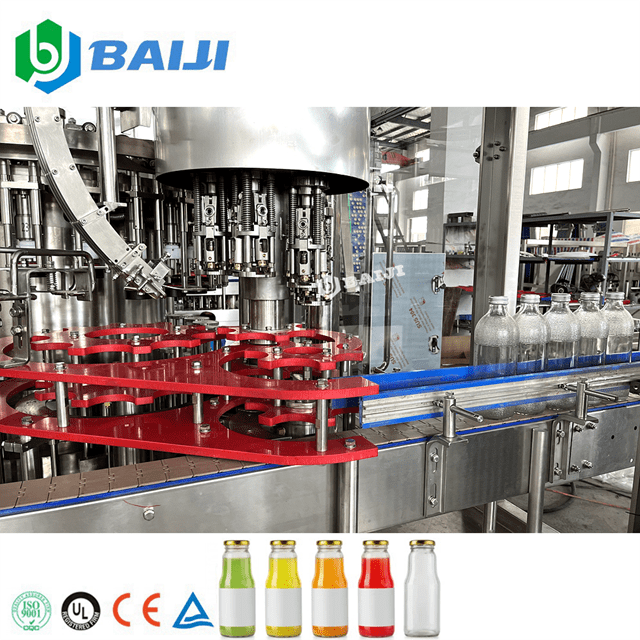

Juice pretreatment system

Sugar melting tank → syrup filter → blending tank → double filter → storage tank → homogenizer → storage tank → vacuum degasser → storage tank → plate type sterilization

Pasteurization tunnel

It is usually used after fruit juice beverage finished hot filling and sealing, when enter the spray tunnel, the water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling. This machine can also be used for secondary sterilization for fruit juice.

Automatic adhesive stick labeling machine

We have different model for your different request, such as single side labeling machine, double sides labeling machine and three sides labeling machine.

Automatic carton box packing machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 12 bottles one package, 6 bottles one package, etc. It is changeable.

water treatment system |  glass bottle depalletizer |

inverted bottle sterilizer |

blow dryer |

date printer |

conveyor system |

SEW motor |

convey lubrication |

automatic lubrication |

oil can be to the main bearing |